Here are some Tweeter housings we fabricated for another great long-standing customer of ours. He purchased an Arc Audio Black Series component set and wanted to get the best sound out of the tweeter as possible. However, the stock location was great, but was in no way going to accommodate the new Arc 1” silk dome tweeter. Not to mention we wanted the dome of the tweeter to have the most acoustically unobstructed “view” of the drivers seat. We knew we were going to have to fabricate a new tweeter housings for him.

How would most shops do this? Well, they would go to their fab room cabinet, pull out fiberglass filer, and just slather it all over the stock tweeter housing to get the depth they needed in order to install the tweeter. Cool… Not so much. Why? Because plastic and fiberglass don’t work well together. When plastic heats up it expands, and when it cools down it shrinks. And when you combine the two, it WILL CRACK!!! All day, every day.

“But I see all these cool installs on the internet and stuff and they aren’t cracked?” Just wait until the first fast temperature change. They will crack. Guaranteed. This is why here at Xclusive Autosound when we make something out of plastic, it is made completely out of plastic. When we make something out of wood we make it completely out of wood. Things we fabricate will last forever and look just as good in 20 years as the day we polished up the install for finished pics.

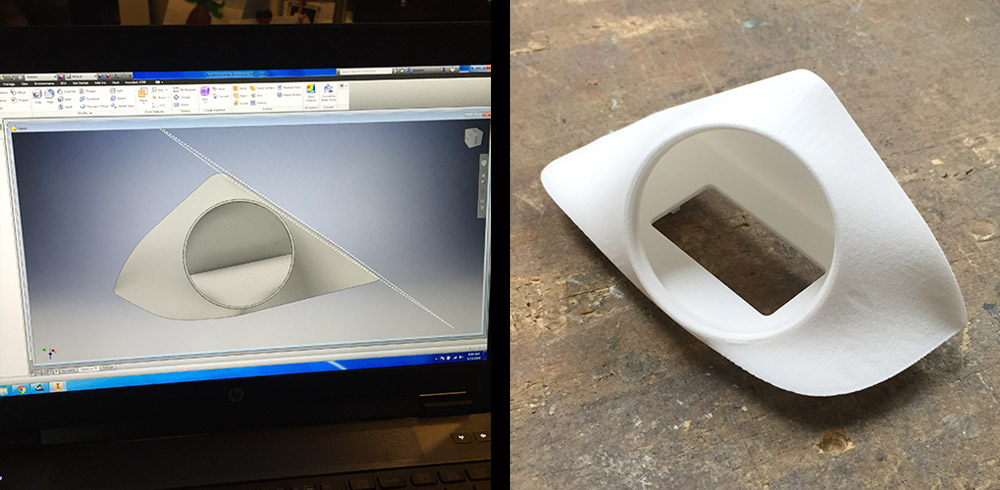

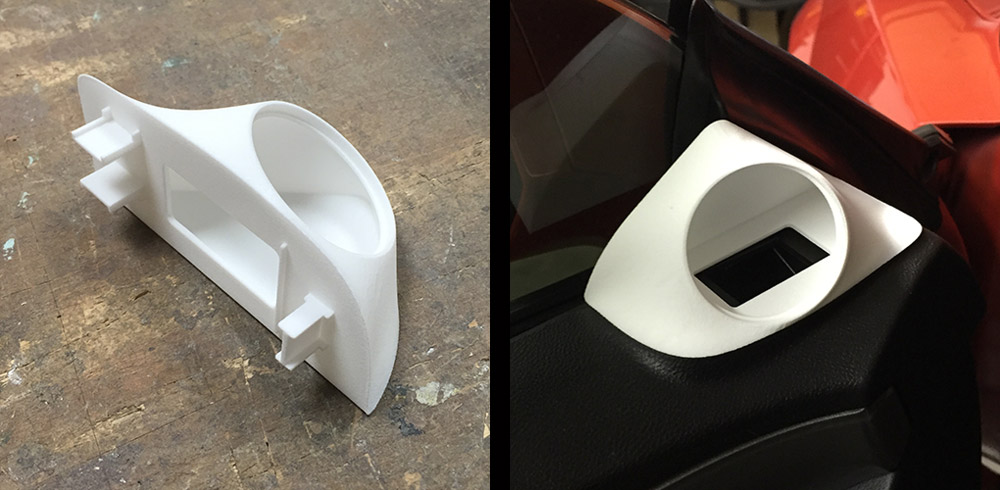

Back to the install. To get the clean install we were looking for, I turned to my CAD software and my extensive engineering background to help build the pods. They look fairly simple to model, however, they are far from it. There were no parallel faces on the stock pod and I needed to make sure I got the feet that hold the clips in just the right spots to make sure they fit the factory panel as good as the stock pods did. Not to mention having to make sure the tweeter housings were aimed properly, which was no small task. The design I came up was clean and elegant, and matched the interior – utilizing the factory grill of the Arc Silk Dome Tweeter. The Tweeter housings were then printed on a 3D printer using 100% nylon – primed and painted to match the interior of the car. Factory clips were put on the new pods and cleanly installed into its new home. The effort was well worth the pay off as they sounded amazing!